Imagine you’re designing the next generation of electric vehicles 🚗💨. Sleek lines, cutting-edge batteries, AI-assisted driving… but deep in its heart, a humble electric motor whirs to life. What if that motor fails under load? What if it vibrates excessively at high speeds? What if it drains power faster than expected? The culprit? Often, it’s unoptimized torque. That’s where the unsung hero of engineering steps in: Motor Torque Testing. 🦸♂️💥 It’s not just data; it’s the key to unlocking reliability, efficiency, and raw power you can count on.

Forget vague promises and theoretical specs. The real world is messy. Friction bites back. Heat warps precision. Materials fatigue. Precision torque testing cuts through the noise, delivering cold, hard facts about how your motor *actually* performs when the rubber meets the road… or the drill bites into steel… or the pump battles thick fluid. It’s the difference between confidence and catastrophic failure. 😰➡️😎

**Why Torque Testing Isn't Just Nice-to-Have… It's Non-Negotiable 🔐**

Let’s ditch the fluff. Torque – that twisting force – is the absolute bedrock of motor performance. It dictates acceleration, determines how much load a motor can handle, influences efficiency, and directly impacts noise, vibration, and lifespan. Guessing torque specs is like building a skyscraper on sand. 🏗️💨 One unexpected peak load, one resonance frequency missed, and the whole project can come crashing down.

Think about the ripple effects:

* Consumer Electronics: A drone motor struggling with sudden wind gusts? Torque instability. That buzz in your premium blender? Torque ripple. Dead phone vibration motor? Insufficient torque for the mechanism. 📱🔋

* Industrial Automation: A robotic arm dropping payloads? Unexpected torque saturation. Conveyor belt jams? Faulty motor torque under startup load. Production line halted = $$$ lost per minute. 🤖💸

* Automotive \u0026 Aerospace: Range anxiety in EVs? Inefficient torque mapping saps the battery. Transmission shudder? Mismatched torque delivery between components. Aircraft actuator lag? Critical torque threshold not met. 🚀✈️ Safety and reputation hang in the balance.

* Medical Devices: A surgical drill stalling mid-procedure? Torque overload protection failure. An infusion pump delivering inconsistent flow? Motor torque variations. Precision is literally life or death. ⚕️❤️

This isn't fearmongering; it's engineering reality. Torque testing shines a brutally honest light on your motor's true capabilities and flaws *before* they become expensive, embarrassing, or dangerous problems.

**Peeling Back the Layers: What *Exactly* Does Motor Torque Testing Reveal? 🧐🔍**

It’s far more than just measuring maximum twist. Sophisticated torque testing tells a comprehensive story:

1. **Torque-Speed Curves: The Motor's Fingerprint 🔄📊:** This is the fundamental map. How much twisting force (torque) does your motor produce at every single point along its speed range? From standstill (starting torque) through its sweet spot (rated torque) and up to its maximum speed (often where torque drops off). This curve reveals efficiency peaks, identifies potential stall points, and shows how the motor handles acceleration and deceleration. Without this map, you're navigating blindfolded.

2. **Efficiency Unmasked ⚡➡️💡:** How much electrical energy is truly converted into useful mechanical work? Torque testing, combined with electrical input measurements (voltage, current, power), calculates efficiency with pinpoint accuracy. Discover where energy bleeds away as heat (losses) – crucial for battery life, thermal management, and operating costs. Finding that 2% efficiency gain? That’s massive in competitive markets.

3. **Ripple \u0026 Cogging: The Hidden Enemies of Smooth Operation 🌊😖:** Does your motor produce a perfectly smooth rotational force? Unlikely. Torque ripple is the unwanted variation in torque output during each rotation. Cogging hysteresis brakes is the resistance felt when trying to rotate the motor slowly by hand (especially in permanent magnet motors). High ripple causes vibration, noise (that annoying whine!), and premature wear on bearings and driven components. Testing quantifies these culprits, enabling design tweaks for silky-smooth operation.

4. **Dynamic Response: How Agile is Your Motor? ⚡💨:** Life isn't static. How quickly does your motor respond to sudden changes in load or speed command? Torque testing under dynamic conditions measures acceleration torque, deceleration torque, and recovery time. Think robotics needing lightning-fast moves or power tools demanding instant grunt. Lag equals lost opportunity (or worse).

5. **Thermal Performance \u0026 Derating 🔥❄️:** Heat is the enemy. Continuous torque testing under load reveals how motor temperature rises over time. Critically, it shows how much the motor’s torque output *decreases* (derates) as it heats up. That motor rated for 10 Nm at room temperature? Might only deliver 7 Nm after 30 minutes under load. Testing defines your safe, sustainable operating envelope.

6. **Durability \u0026 Endurance Testing 🔄⏳:** Will your motor last? Accelerated life testing under controlled torque loads simulates years of wear and tear in weeks or months. It reveals failure modes – bearing wear, magnet demagnetization, insulation breakdown – proving (or disproving) reliability claims and warranty periods. Peace of mind is quantifiable.

**Beyond the Bench: The Tools Making Precision Possible 🔧🔬**

Gone are the days of crude lever arms and spring scales. Modern motor torque testing leverages sophisticated technology:

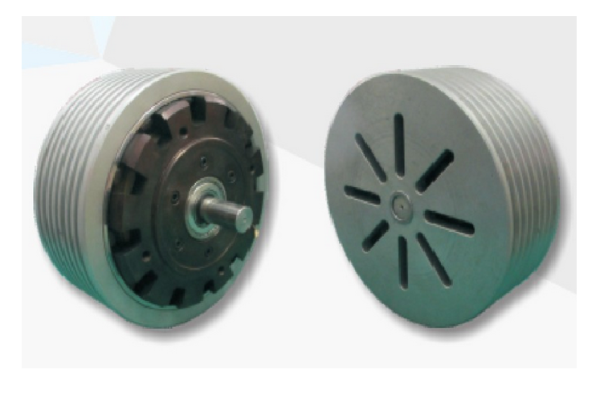

* **High-Fidelity Torque Transducers:** The heart of the system. These precision sensors (strain gauge, magnetoelastic, or optical-based) are inserted directly into the drive line between the motor and its load. They measure the actual twisting force with incredible accuracy and resolution, often capturing thousands of data points per second.

* **Dynamic Dynamometers:** These aren’t your grandpa’s brakes. Modern dynos provide the controllable, variable load the motor works against. They can simulate real-world conditions like vehicle inertia, pump pressure, or fan resistance. Types include:

* Eddy Current Dynos: Excellent for high-speed applications.

* Hysteresis Dynos: Smooth control, great for low torque.

* Regenerative AC/DC Dynos: Highly efficient, can feed power back to the grid, ideal for high-power and endurance testing.

* Powder Dynos: Robust for high-torque, low-speed applications.

* **Precision Encoders/Speed Sensors:** Lock-step with torque measurement, accurately tracking rotational speed and position is essential for mapping torque-speed curves and analyzing dynamics.

* **Integrated Power Analyzers:** Simultaneously capturing *all* electrical inputs (V, I, P, Q, S, PF, harmonics) alongside torque and speed is non-negotiable for true efficiency calculations and understanding power quality impact.

* **Thermal Imaging \u0026 Contact Sensors:** Monitoring hot spots on the motor housing, windings (indirectly), and bearings provides critical thermal performance data.

* **Data Acquisition (DAQ) \u0026 Control Systems:** The brain of the operation. High-speed DAQ captures every signal from the sensors. Sophisticated control software manages the dynamometer load profile, runs automated test sequences (like mapping torque-speed curves), and provides real-time visualization and post-processing of mountains of data.

* **Environmental Chambers (Optional but Powerful):** Testing motors under extreme temperatures (-40°C to +150°C+) or controlled humidity reveals performance shifts critical for automotive, aerospace, and outdoor applications.

**The Tangible Wins: What Precision Torque Testing Delivers Straight to Your Bottom Line 🏆💰**

Investing in rigorous torque testing isn't just a technical exercise; it's a strategic business decision with concrete returns:

* **Superior Product Performance \u0026 Reliability:** Deliver motors that meet spec *consistently*, handle real-world stresses, and last longer. Happy customers buy more and recommend you. ✅

* **Optimized Efficiency = Competitive Edge:** Find those hidden energy losses. A more efficient motor means smaller batteries, lower operating costs (energy bills!), extended range (EVs), reduced cooling needs, and greener credentials. 🌱💸

* **Reduced Development Time \u0026 Cost:** Identify design flaws *early* with physical validation. Avoid costly late-stage re-designs, production tooling changes, or catastrophic field failures. Fail fast, learn faster, succeed sooner. ⏱️🚀

* **Enhanced Safety \u0026 Risk Mitigation:** Prove your motor won't fail dangerously under overload or extreme conditions. Critical for medical, automotive, aerospace, and industrial applications. Avoid lawsuits, recalls, and brand damage. 🛡️⚖️

* **Faster Time-to-Market with Confidence:** Comprehensive test data provides irrefutable evidence for design sign-off and regulatory compliance (e.g., efficiency standards like IE, DOE, ErP). Speed up certification. 🚪➡️📈

* **Validation for Marketing Claims:** Back up \"high torque,\" \"ultra-efficient,\" or \"whisper-quiet\" claims with hard data. Build trust and credibility. 📣🔒

* **Diagnostics \u0026 Problem Solving:** When field issues arise, replicated torque testing in the lab is the fastest way to diagnose root causes – be it a design flaw, manufacturing defect, or unexpected usage pattern.

**Choosing Your Torque Testing Partner: It's About More Than Just Machines 🤝🧠**

Not all test labs or equipment are created equal. Here’s what truly matters:

* **Expertise \u0026 Experience:** Do they *really* understand motors – your specific type (BLDC, PMSM, Induction, etc.), application, and industry nuances? Can they interpret the data and offer actionable insights, not just pretty graphs?

* **Testing Scope \u0026 Capabilities:** Can they handle your motor's full range? Power? Torque? Speed? Dynamic requirements? Environmental needs? Do they have the right dynamometer and sensors? Verify their calibration traceability (e.g., ISO 17025).

* **Data Depth \u0026 Transparency:** Will you get raw data, detailed reports, and clear explanations? Or just a summary sheet? Look for systems that provide comprehensive data logging and flexible analysis tools.

* **Customization \u0026 Flexibility:** Can they adapt test profiles to simulate *your* specific application's load cycle? Or are they limited to standard tests?

* **Scalability \u0026 Support:** Can they grow with your needs? What about ongoing maintenance, calibration, and technical support for the equipment? Can they assist with integrating testing into your R\u0026D or production workflows?

**The Future is Spinning: Where Torque Testing is Headed 🔮🌀**

The field isn't standing still. Watch for these trends:

* **Integrated Digital Twins:** Coupling physical torque test data with sophisticated simulation models creates a powerful \"digital twin\" of the motor. Predict performance and reliability in untested scenarios, accelerating virtual prototyping. 💻🌐

* **AI-Powered Analytics:** Machine learning algorithms sifting through vast torque, vibration, acoustic, and thermal datasets to identify subtle patterns, predict failures, and automatically optimize control algorithms faster than humanly possible. 🧠📈

* **Ultra-High-Speed Testing:** As motors spin faster for applications like turbochargers and high-speed spindles, testing equipment is pushing bandwidth limits to capture critical transient data.

* **In-Line Production Testing:** Moving beyond R\u0026D labs, automated torque testing stations are becoming crucial for 100% quality verification on the production line, catching defects before shipment. 🏭🛠️

* **Focus on NVH (Noise, Vibration, Harshness):** Torque ripple testing is increasingly integrated with advanced vibration and acoustic analysis to deliver holistic NVH solutions for quieter, smoother products. 🔇🎯

* **Standardization \u0026 Benchmarking:** As industries mature, standardized torque testing protocols (beyond just efficiency) are emerging, enabling more meaningful comparisons between motor manufacturers.

**Stop Gambling with Guesswork. Start Building on Certainty. 🎲➡️🏗️**

In a world demanding more power, greater efficiency, and unwavering reliability, leaving motor performance to chance is a high-stakes gamble you can't afford. Precision torque testing transforms uncertainty into actionable intelligence. It transforms prototypes into robust products. It transforms potential into proven performance.

Whether you're an ambitious startup crafting the next disruptive tech or an established powerhouse optimizing your flagship motor line, torque testing is your indispensable ally. It’s the rigorous validation that separates market leaders from the also-rans. It’s the science that fuels engineering excellence.

Don’t just build motors. Build confidence. Build performance. Build success. 🔥

Ready to put your motors to the ultimate test and unlock their true potential? The tools, the expertise, and the path to peak performance are waiting. Let's get spinning. 🚀